Anesthesia Machine Service

Ensuring Precision, Safety, and Reliability

At Vetamac, we understand that the heart of your veterinary practice is the anesthesia machine. To provide the best possible care to your animal patients, it's crucial that this vital equipment operates with precision, safety, and reliability. That's where our comprehensive Anesthesia Machine Service comes into play. We're dedicated to ensuring that your anesthesia machine performs at its best, every time.

What Our Anesthesia Machine Service Includes

Our Anesthesia Machine Service is a thorough and meticulous process designed to verify, test, pressure check, and calibrate every critical component of your machine. Here's what you can expect when you choose Vetamac.

High and Low-Pressure Circuits

We conduct a rigorous examination of the high and low-pressure circuits to ensure that they are free from leaks, blockages, or any irregularities that might affect performance.

Flowmeter and Oxygen Flush Valve

Our technicians verify the accuracy and functionality of the flowmeter and oxygen flush valve, guaranteeing precise control over the flow of gases.

Rebreathing Circuit and Accessories

We inspect the rebreathing circuit and its accessories, checking for any signs of wear or damage that could compromise safety during procedures.

Non-Rebreathing Circuit and Accessories

Similar to the rebreathing circuit, we scrutinize the non-rebreathing circuit and associated components for integrity and performance.

Gas Evacuation System

Our service includes a thorough evaluation of the gas evacuation system to ensure the safe removal of waste gases from the operating area.

Overall Machine Condition

We perform a comprehensive assessment of the overall condition of your anesthesia machine, identifying any potential issues that require attention.

Replacement Parts

Throughout the service process, if any components are found to be faulty, worn, or in need of replacement, our team will promptly source and install genuine manufacturer-approved replacement parts. We believe in using only the highest-quality components to maintain the reliability and safety of your anesthesia machine.

Calibration Check

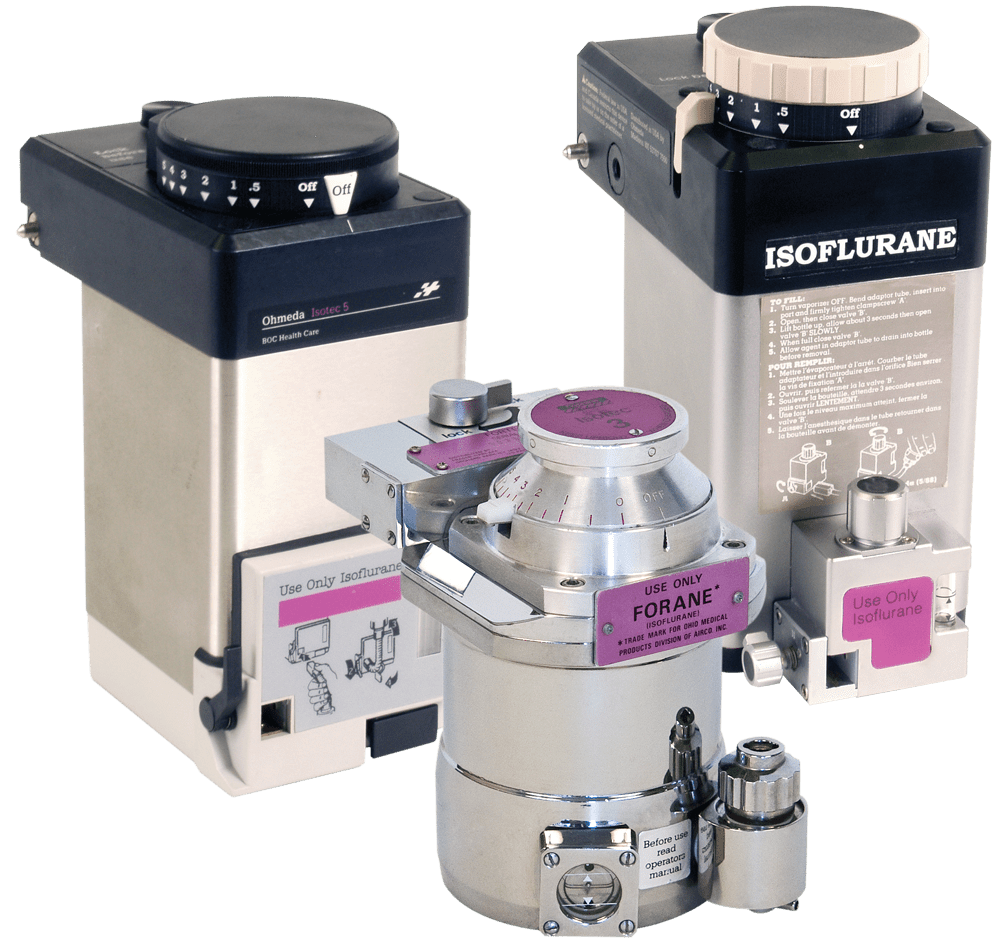

Our meticulous service includes a calibration check of each vaporizer. This involves a visual examination of the vaporizer and a verification of its output through the full range of settings, ensuring that it delivers precise concentrations of anesthetic agents.

Experience Excellence with Vetamac's On-Site Anesthesia Machine Service

With Vetamac's Anesthesia Service, you can be confident that your equipment is in the hands of experts who prioritize precision, safety, and reliability. We understand the critical role anesthesia machines play in your veterinary practice, and our commitment to excellence ensures that your patients receive the highest level of care. Choose Vetamac for unmatched expertise in veterinary anesthesia services.

To experience the Vetamac difference, please take a moment to fill out the form. Our team is ready to assist you with top-notch anesthesia services tailored to your needs.

On-Site Anesthesia Machine Service Request

Helpful Links

Home

Store

Services

Service Technician Locator

Who We Are

Testimonials

Events

Resources

Contact

Contact us

130 Roth Court, Suite 100

Rossville IN 46065

Toll-Free 800-334-1583

Office 765-379-3040

Fax 765-217-4236